Point Machine Diagnostic System

Point Machine Diagnostic System

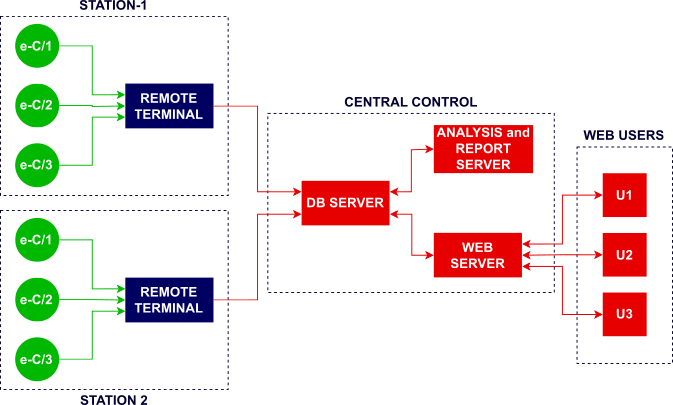

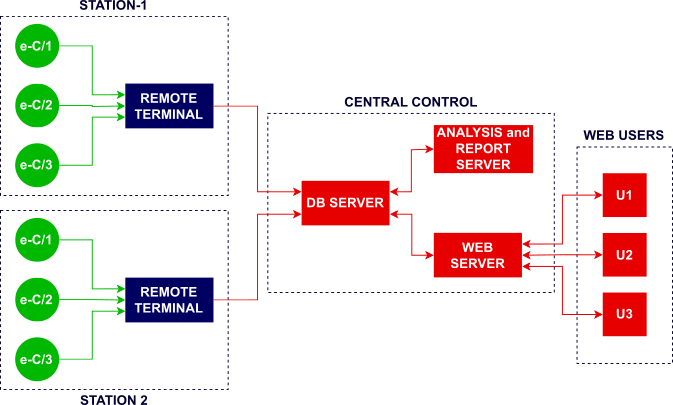

e-Current is especially designed to capture current graphs of railway switch point systems which can also be used current measurement of point heating system.

e-Current is especially designed to capture current graphs of railway switch point systems which can also be used current measurement of point heating system.

Technical Specification

Software

Analyses the Instant current graphs by comparing with reference signals and visualize results on user web Interface.

Creates alarms In advance In case of current graph discrepancies before problem affects operation of trains.

In case of any failure. Informs maintenance team to be transferred to the problematic point as fast as possible.

Easily determines which switch point has caused the failure In multiple switch point turnout systems which are used on High Speed Railway Lines.

Prepares statistic reports of each switch point In system grouping by turnouts, stations and lines In order to represent the operational health status of all the turnouts at once.

Web based user Interface can be accessed from all the operating system as well as mobile devices.

Reports the problems by web user Interface, e-mail and SMS.

Technical Specifications

Software

Analyses the Instant current graphs by comparing with reference signals and visualize results on user web Interface.

Creates alarms In advance In case of current graph discrepancies before problem affects operation of trains.

In case of any failure. Informs maintenance team to be transferred to the problematic point as fast as possible.

Easily determines which switch point has caused the failure In multiple switch point turnout systems which are used on High Speed Railway Lines.

Prepares statistic reports of each switch point In system grouping by turnouts, stations and lines In order to represent the operational health status of all the turnouts at once.

Web based user Interface can be accessed from all the operating system as well as mobile devices.

Reports the problems by web user Interface, e-mail and SMS.

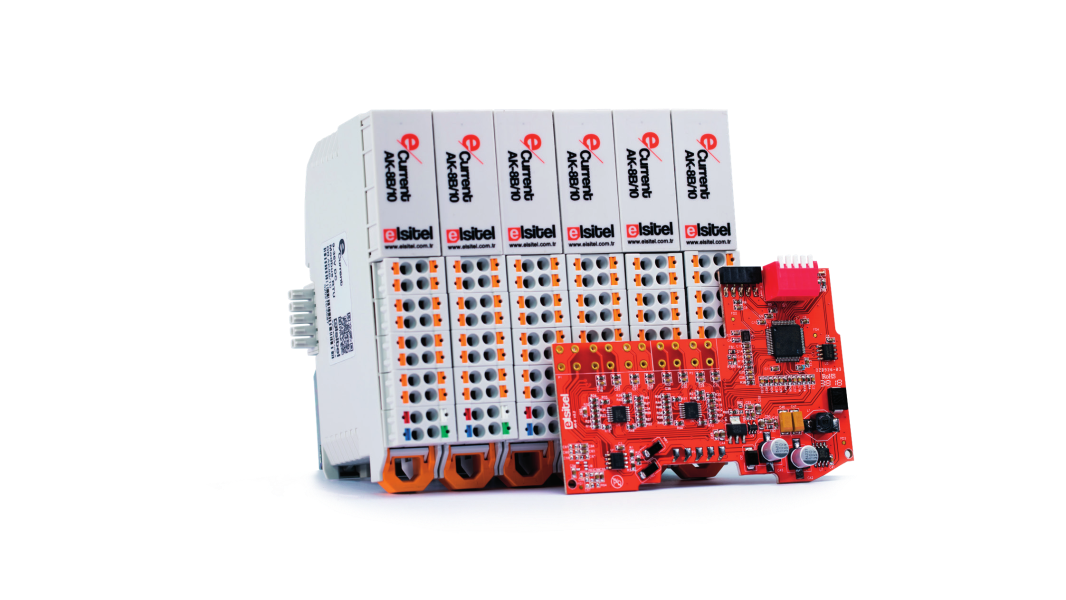

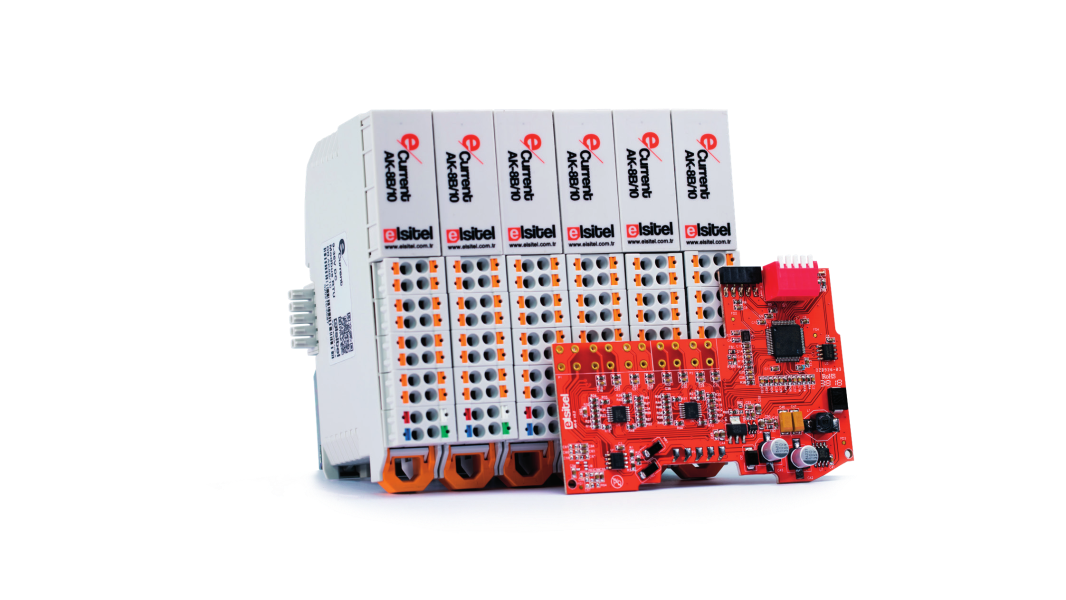

Hardware

Measures current totally electrically Isolated from the system to be monitored.

Control card can monitor up to 8 current channel.

Communicates with station terminal via RS485 interface.

Each Current channel can capture 200 samples/second up to 15 seconds.

Each station terminal can control 20 control cards In total 160 current channels.

Operating Voltage: 9-36V DC

- Operation Temperature: -40°C to +70˚C

Current Channel: 8

Communication: RS485

Fixation: DIN Rail

Dimensions: 115 x 20 x 78 mm (HxWxD)

Hardware

Measures current totally electrically Isolated from the system to be monitored.

Control card can monitor up to 8 current channel.

Communicates with station terminal via RS485 interface.

Each Current channel can capture 200 samples/second up to 15 seconds.

Each station terminal can control 20 control cards In total 160 current channels.

Operating Voltage: 9-36V DC

Operation Temperature: -40°C to +70˚C

Current Channel: 8

Communication: RS485

Fixation: DIN Rail

Dimensions: 115 x 20 x 78 mm (HxWxD)

Technological and Innovative Aspects of e-Current

Having a structure that is completely isolated from the systems to be measured.

Not needing any adaptor or additional attachments while installing.

Delivering advance warnings to users via web interfaces, text message and e-mail.

Increase the stability of the signaling systems used in all sub systems due to the low production costs.

Ability to work in many different systems due to being able to be integrated into the different electric/electronic devices and equipment.

- Less BOM for point heating system.

Monitoring power consumptions of each heating element by measuring instant current values.

Technological and Innovative Aspects of e-Current

Having a structure that is completely isolated from the systems to be measured.

Not needing any adaptor or additional attachments while installing.

Delivering advance warnings to users via web interfaces, text message and e-mail.

Increase the stability of the signaling systems used in all sub systems due to the low production costs.

Ability to work in many different systems due to being able to be integrated into the different electric/electronic devices and equipment.

- Less BOM for point heating system.

Monitoring power consumptions of each heating element by measuring instant current values.